Bridgestone Americas, Inc. (Bridgestone) today announced it will exhibit at the Transportation and Maintenance Council’s (TMC) Annual Meeting and Transportation Technology Exhibition in Atlanta, Georgia, March 5-8. Bridgestone will showcase its portfolio of integrated technologies, best-in-class services and intelligent products including Bandag®, the Bridgestone business dedicated to the research, development and manufacturing of premium retreaded tires.

In booth #3012, Bridgestone will demonstrate how Ecopia™ commercial truck tires and Bandag FuelTech™ retreads work together to provide fleets with maximum fuel efficiency and the lowest total cost of ownership. Research has shown Bridgestone engineers the most retreadable tire casings in the industry.*

“At Bridgestone we focus on providing fleets with a reliable and holistic tire solution to maximize performance and improve profitability,” said Joseph Saoud, president, truck bus radial, Bridgestone Americas Tire Operations. “We look forward to connecting with industry professionals at TMC and demonstrating our commitment to furthering smart, efficient and sustainable mobility.”

Bridgestone will display the following offerings at its TMC booth:

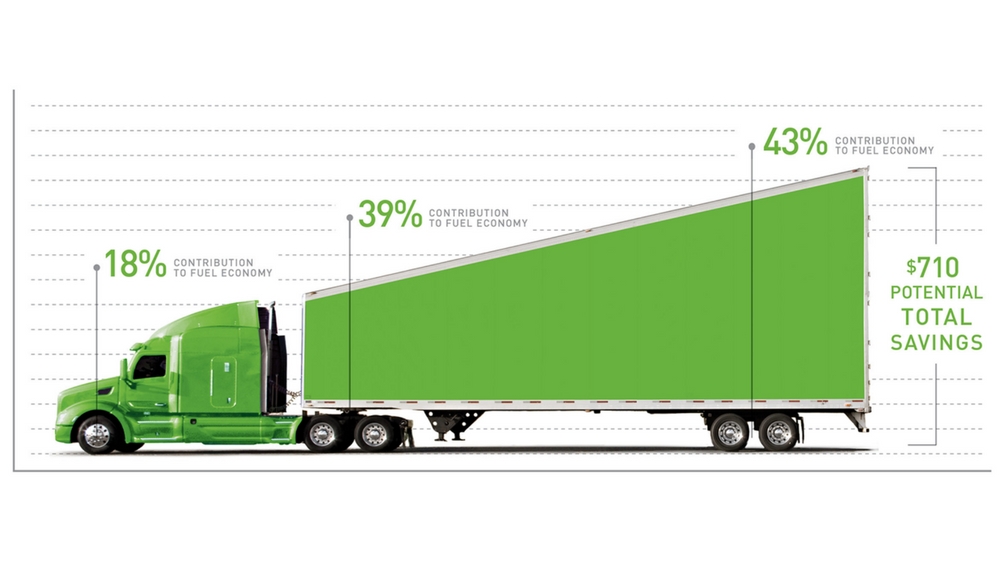

- Bridgestone EcopiaTM tire line: Bridgestone Ecopia tires are an industry leader in fuel efficiency featuring a low rolling resistance design and advanced tread compounds for eco-performance. In fact, fleets that use Bridgestone Ecopia tires in all three wheel positions have the ability to save $1,349 per truck annually in comparison to competitive products.**

- Bandag FuelTech™ retreads: Bandag FuelTech retreads perform like comparable new tires.*** When compared against both new tires and retreads, Bandag FuelTech retreads provide fuel-efficiency gains and help to lower the total cost of ownership for fleets.

- In-booth virtual reality (VR) experience: The VR training will provide an inside look at Bandag retread technology through a tour of the Bandag equipment manufacturing plant in Muscatine, Iowa.

To learn more about Bridgestone Ecopia tires, Bandag FuelTech retreads and other total tire solutions that TMC attendees will experience, visit https://commercial.bridgestone.com/en-us/index.

*Retreadability rate is based on BASYS™ retread manufacturing data accumulated from more than 15 million casings from 2012 through 2016, including Bridgestone, Michelin and Goodyear casings.

**Bridgestone R283A Ecopia tire (in steer position), M710 Ecopia tire (in drive position), and R197 Ecopia tire (in trailer position) in size 295/75R22.5 load range G, compared to the equivalent size and load range of Michelin X-Line Energy Z tire (in steer position), X-Line Energy D tire (in drive position), and X-Line Energy T tire (in trailer position), and to the equivalent size and load range of Goodyear Fuel Max LHS tire (in steer position), Fuel Max LHD G505D tire (in drive position), and Fuel Max LHT tire (in trailer position). Rolling resistance and wear results obtained from Bridgestone internal TLCC model which incorporates third party SAE J1269 rolling resistance testing and measures results over the life of the tire. Savings calculated assuming $3.00/gallon fuel cost, 5/32nds pull point, 80,000 lbs. total vehicle weight, for a class 8 tandem-drive axle tractor and single trailer combination traveling 120,000 miles/year. Projected wear results based on field test data across multiple users in long haul fleet application. Projected wear of Goodyear FuelMax LHT tire assumes same wear as Bridgestone R197 Ecopia tire. Actual results will vary depending on several factors such as tire size, operating conditions, maintenance, road conditions, and driving style.

*** Comparable tires based on, among other things, tread type and application.