Tire Construction

See how chemistry, physics and engineering come together to provide a safe, comfortable ride. While designs vary by product and manufacturer, an average tire contains well over 100 separate components. Tires can include natural rubber, synthetic rubber, steel, nylon, silica (derived from sand), polyester, carbon black, petroleum, etc. See photos of tire materials here. The combination of ingredients and processes used by different manufacturers leads to different performance characteristics for every tire in the market today. Watch this video from the U.S. Tire Manufacturers Association to see how passenger tires are made.

How Tires Are Made

Although rubber is the main material used in tires, there are many others. Some tires are composed of as many as 200 different raw materials, which are combined with rubber compounds to create the various components of a tire’s construction. Learn more about the compounds and materials found in tires and tire construction features from the US Tire Manufacturers Association.

Rubber compounding is like mixing a cake recipe. Different ingredients are mixed to produce compounds with specific characteristics. The outside tread compound provides traction and mileage, whereas the rubber located inside the tire adheres to the belt system and provides stability to the tread area. Rubber compounds may differ due to the variety of materials used in the tire.

Materials used by each tire manufacturer are chosen with individualized technology in mind. Each tire component is designed to provide benefits specifically related to its function while still working with the other components. Learn more about how a tire is made from the U.S. Tire Manufacturers Association.

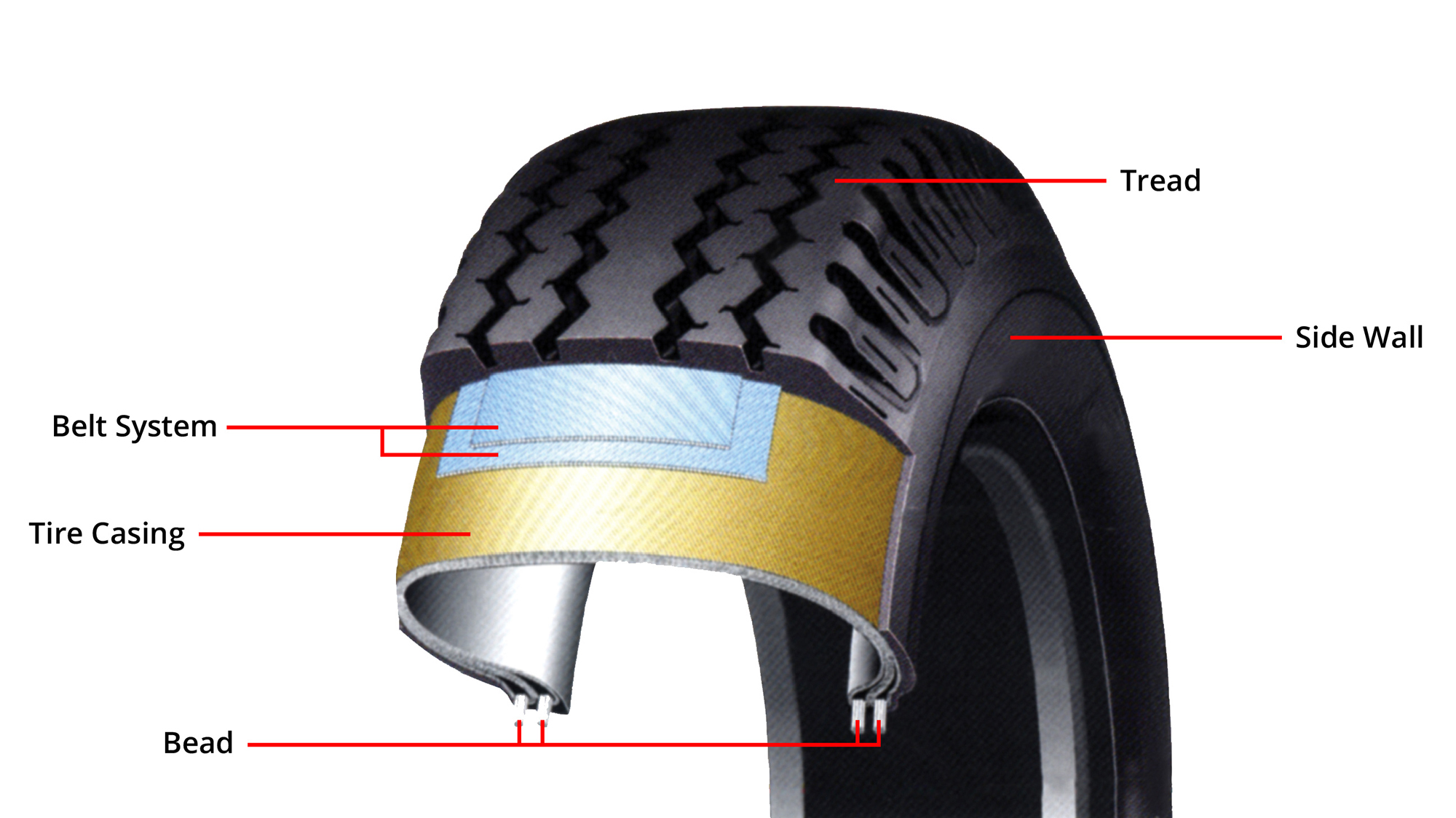

Tire components are assembled like a puzzle and molded together in the curing process, which causes the tire components and rubber compounds to adhere to their surrounding components to create a singular product. The belt system's main function is to provide stability to the tire’s tread area, which contributes to wear, handling and traction. The belt system also works in unison with the tire's sidewall and tread to achieve traction and cornering capabilities.

The tire casing is the body of the tire and includes components such as the Bead, Sidewall, Body Ply and Innerliner. Basically everything except the Tread and Belt System.

Most passenger tire casings are multi-ply and incorporate polyester, nylon or rayon cords within the casing rubber compound. These cords add strength to the casing rubber. Polyester is commonly used because it provides good rubber adhesion, excellent strength and good ride characteristics at a relatively low weight, and it also exhibits heat dissipation characteristics. Other fabric materials used in the tire casing include nylon and rayon, which both exhibit slightly different benefits tuned to specific tire requirements.

A special rubber compound is used in the sidewall of the tire to add flexibility and weather resistance. Some tires, such as performance tires, may also incorporate steel and/or nylon inserts to provide quicker steering response.

Tire bead bundles secure the tire to the wheel. They are large steel cords wound together to form a cable or ribbon-type configuration. The casing plies are looped around the bead bundles to hold them in place. Bead filler, a rubber compound, is incorporated within the bead configuration and extends into the sidewall area. The rubber compound used on the outside bead area is usually a hard, durable compound that withstands the rigors of mounting the tire to the wheel.

A specific rubber compound is used as an air seal inside the tire. This innerliner layer has no cord reinforcing and is similar to an inner tube.

The belt system is placed on top of the casing during the construction process. The belt system's main function is to provide stability to the tire’s tread area, which contributes to wear, handling and traction. Steel is the most common belt material. Steel belts provide strength and stability to the tread area without adding a lot of weight to the tire. Usually two plies of steel cord placed at opposite angles make up the belt system. The most common belt configuration is two stacked plies of steel cord.

The tread slab is placed on top of the belt system during the manufacturing process. Tread usually contains two rubber compounds: tread base and tread cap. Tread base compounds adhere to the belt system when the tire is cured, improving durability and stabilizing the layers of polyester cords, called plies, which make up the under tread. Tread cap is typically made with an abrasion-resistant, higher-grip rubber compound, which works with the tread base and tread design to provide traction and mileage. The tire's tread pattern is molded into the tread cap rubber during the curing process.

Passenger tire and light truck tire constructions vary because of their uses and operating conditions. Light truck tires are designed to operate in more severe conditions, frequently carrying greater loads and going off-road. Light truck tires may have an extra casing ply, an extra belt, a stronger belt steel cord and/or a larger bead with more sidewall rubber, which is why light truck tires are heavier than passenger tires. Light truck tires are typically capable of higher load carrying capacities.